TF1800 BGA and SMD Rework System

Conventional resistance coil heating technology has been successfully used in convective rework stations for decades to install and remove a variety of BGA, QFN, CSP, CGA, PoP, Flip Chip, 0201 and other bottom terminated components. However, today’s extremely high thermal mass boards, ultra-fine pitch components and challenging production rework environments demand greater process control, thermal performance and faster throughput than ever before.

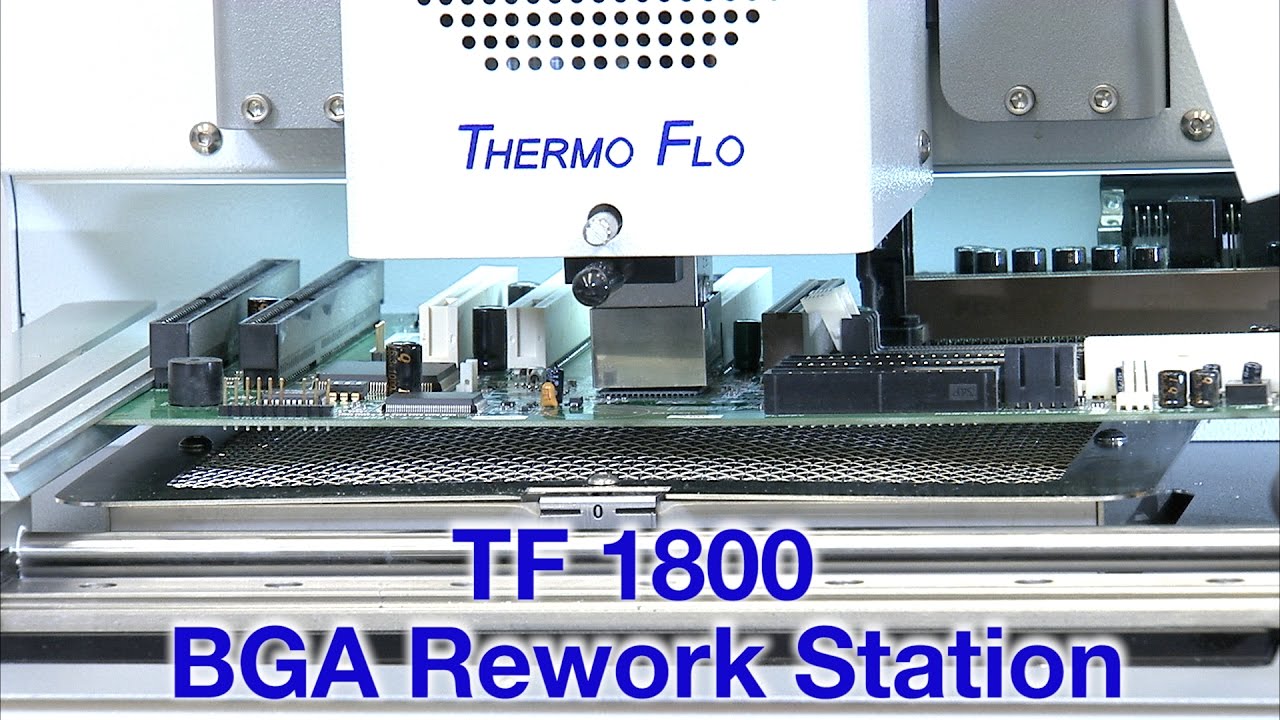

Enter PACE’s TF 1800 BGA/SMD Rework System. With its groundbreaking, patented Inductive-Convection Heating Technology, the TF 1800’s top-side heater reaches the target temperature in just seconds for safe, rapid solder joint reflow in virtually any component installation or removal application.