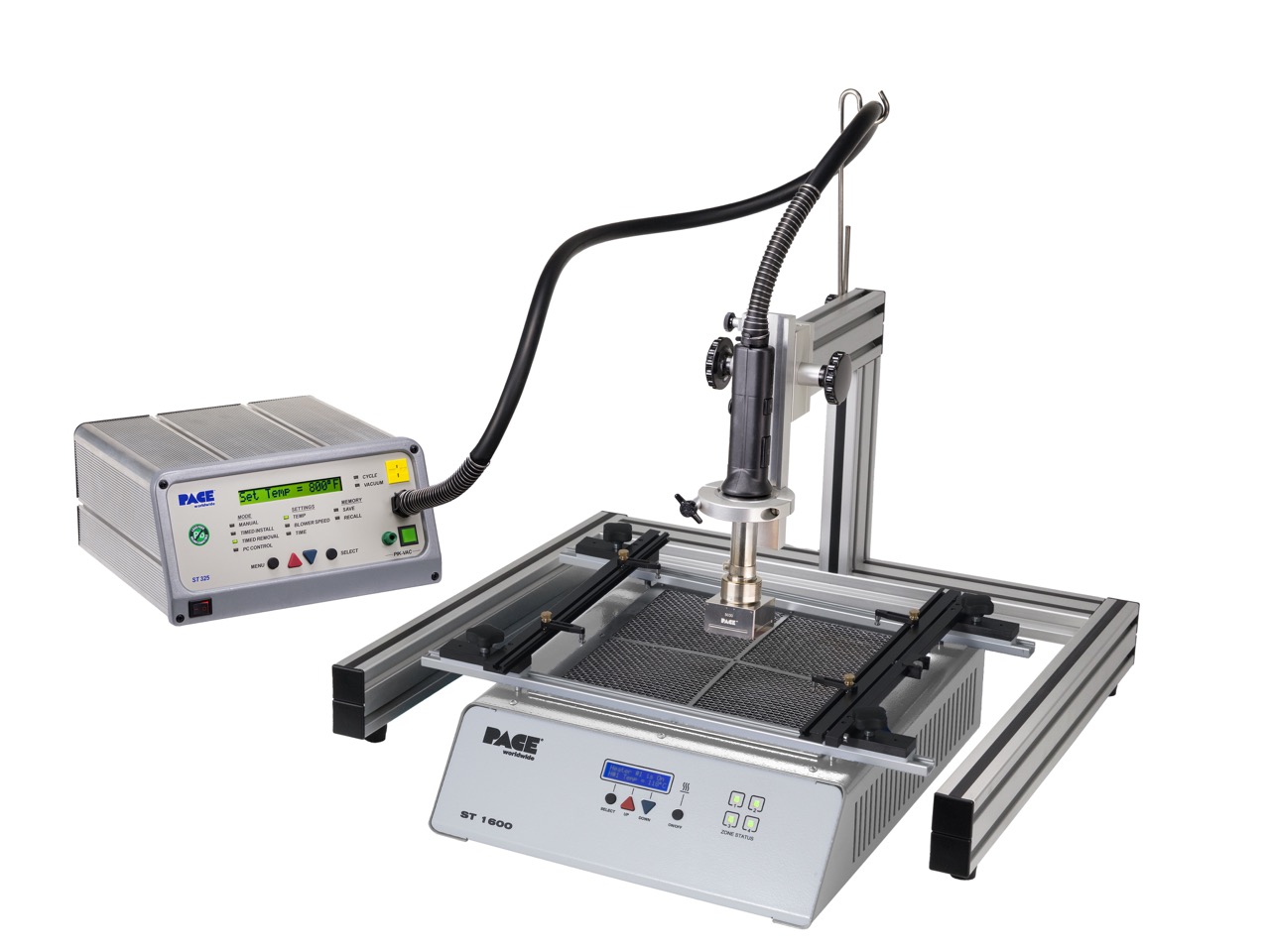

ST925 Convective & Infrared SMT Rework System

The ST 925 SMT Rework System has been updated with our ST 1600 preheater, replacing the discontinued PH-100 preheater.

The ST925 combines three popular PACE products together into one convenient, low-cost SMT Rework System. The system is comprised of the ST325 Programmable Convective/Hot Air Rework Station, the ST1600 InfraRed Pre-Heater and ST500A Z-Axis Platform. Together, the system provides a 575 Watt convective top-side heater plus a 1600 Watt IR bottom-side preheater which allows operators to safely rework PCBs. Together, the system provides a powerful 575 Watt convective top-side heater plus a 1600 Watt IR bottom-side preheater which allows operators to safely rework PCBs for fast, efficient soldering, rework or repair, even on the highest mass, thermally challenging, lead-free PCBs.