IR4100 Infrared BGA and SMD Rework Station

The IR4100 can easily install and remove BGA, QFN, μBGA/CSP, Flip Chip and other SMD's. Featuring a 500W infrared (IR) top heater and 1900W IR bottom preheater, comprised 1x1000W IR Heater and 6x150W Peripheral IR Heaters. The IR4100 does not require nozzles. A specially-developed IR pyrometer provides non-contact, real-time, closed-loop temperature control throughout the reflow process. A Sodr-Cam Reflow Camera comes standard, allowing you to watch the entire reflow process in real time. The IR4100's newly designed Windows-based software makes profiling incredibly simple for even the most advanced applications, providing intuitive set-up, multi-stage profiling, on-the-fly profile adjustment, flux-dipping, unlimited profile storage and much more.

The IR4100 is specifically designed to rework large PCBs as big as 24"(610mm) x 24"(610mm). With its 6 independently controlled peripheral IR bottom heaters, the operator will be able to create an effective heating profile with ease, without fear of reflowing nearby components or joints. The IR4100's uniquely designed Board Support Beam will keep any board from possible warping or sagging during a heating profile.

Made in the USA.

-

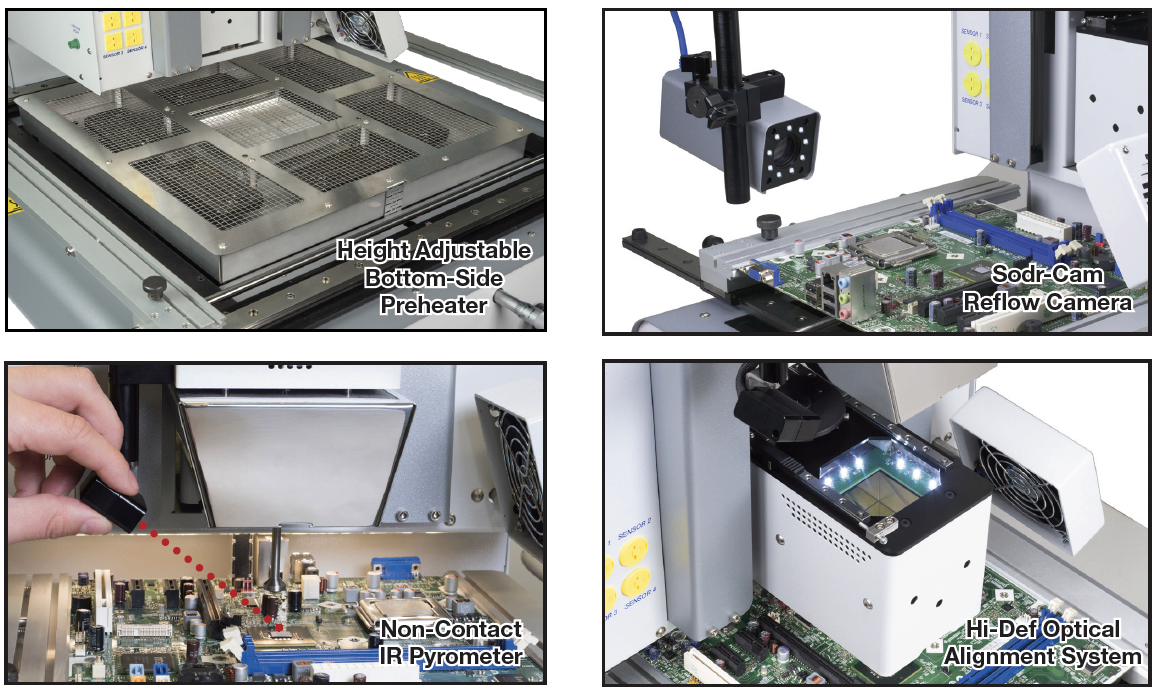

FeaturesNon-Contact IR PyrometerUltra-High Precision Placement CapabilityHigh Sensitivity Vacuum PickSodr-Cam Reflow CameraHeight Adjustable Bottom-Side PreheaterHigh-Definition Optical Alignment SystemQuad-Field Imaging for Large/Fine Pitch BGA'sIntegrated Board Support BeamPower Distribution GraphSensor Offset24" x 24" (610mm x 610mm) Board Holder6 Independently Controlled Peripheral Bottom HeatersMade in the USA

-

Specifications120 VAC Unit Power Requirement120 VAC, 50/60 Hz (2400 Watts maximum) Requires dedicated 20 A supply230 VAC Unit Power Requirement230 VAC, 50 Hz (2400 Watts maximum) Requires dedicated 10 A supplyDimensions737mm (29”) H x 1118mm (44”) W x 965mm (38”) DWeight (Without Computer)90kg (200lbs)Bottom-side PreheaterMedium/Long wave IR, 1900 Watts with array of 7 IR emitters capable of preheating large, high mass assembliesAdjustable Bottom Heater Working HeightAdjustable working height from lowest position up to 38mm (1.5”) closer to the PCBSensitivity Vacuum PickPick is counterweight balanced,and utilizes an optical sensor and precision high temperature linear ball bearings ensuring delicate placement and pick up of parts from PCB. Includes six (6) Vacuum PicksPrecision Placement CapabilityAdvanced professional placement system utilizing a stepper motor and position encoding provides smooth, precise movement, with no drift, allowing for repeatable and accurate placementPlacement AccuracyStepper motor with precision positioning of to 28μm (.0011") accuracyBoard Support CapabilityIncorporates adjustable/removable Board Support Beam; Plus up to four stationary adjustable height support pins; Prevents PCBs from sagging/warping during reworkMaximum Target TemperatureEach profile zone has a maximum target temperature of 328 degrees C. (624 degrees F)Precision PCB HolderAdvanced table features micrometer X & Y adjustment, extruded board holder arms, spring loaded, with T-slots and movable clamps for both large and irregularly shaped boards with non-uniform edgesMaximum/Minimum PCB SizeMaximum: 610mm x 610mm (24” x 24”); Minimum: N/AMaximum/Minimum Component SizeMaximum: 65mm (2.5") x 65mm (2.5"); Minimum: 1mm Sq.IR Pyrometer and Thermocouple InputsA specially developed IR sensor provides non-contact, real-time, closed-loop temperature control throughout the reflow process. In addition, four (4) thermocouple inputs provide additional real-time monitoring (includes 2 K-type thermocouples)High Definition Optical Alignment SystemVision Overlay System (VOS) with High Definition (1080p) color camera, integrated frame grabber, dichroic beam-splitting prism, independently controlled LED illumination for component and PCB. Up to 240x zoom, and doesn't need routine calibrationSodr- CamAllows the developer to watch the entire reflow process in real time to verify solder melt. The camera arm rotates to provide a 180-degree view at a fixed distance, for minimal focus adjustment and ease of use.Motorized Optics HousingAutomatically controlled, retractable optics housing protects Vision Overlay System from dirt and contaminationQuad-Field ImagingFor large component alignment (including fine-pitch QFPs), allows up to four opposite corners of a large component (and its pads) to be viewed under higher magnificationSingle Axis OperationAll operations, including component pick-up, alignment, placement, reflow & active cooling are completed in a single axis, eliminating risk of component movement after placement and reflowAuxiliary Cooling FanStandard, for secondary cooling of the PCBSoftwareIntuitive, user-friendly, Windows-compatible software guides operators through profile development and execution; No cost upgrades on IR3100/4100 softwareComputer SystemWindows 10 PC with wireless mouse/keyboardVideo Monitor607mm (24") wide screen flat panel monitor (includes Monitor Arm Mounting Kit)Video InputsUSB 3.0Component NestsTwo (2) removable and adjustable Component Nests provided for perfect centering of components, in preparation for vacuum pick-up/placement. Unique component holding system for parts under 5mm Sq.Flux Dip PlateIncluded: allows for automated flux dippingPV-65 Pik-Vac Vacuum WandIncluded: provides a manual vacuum pick-up capability for handling SMDs, incorporates new 15-minute auto-off featureWarrantyOne Year Limited Warranty

-

More Information

Advanced Features

• Ultra-High Precision Placement Capability: Motorized reflow head is driven by advanced stepper motor system providing smooth, high precision, repeatable movement with no drift, allowing for soft landing of components and 28μm (.0011") placement accuracy.

• High Sensitivity Vacuum Pick: New Vacuum Pick design is more robust, utilizes an optical sensor, is counterweight balanced, and employs precision high-temperature linear ball bearings for maximum accuracy and sensitivity in placement and pick-up.

• Sodr-Cam Reflow Camera: Provided Sodr-Cam allows the operator to verify the entire reflow process, including the exact moment of solder melt.

• Height Adjustable Bottom-Side Preheater: High powered (1000W) IR preheater, and 6x150W peripheral heaters, is height adjustable from standard position up to 38mm (1.5") closer to the PCB for the most challenging high-thermal -mass boards.

• High-Definition Optical Alignment System: Automated Vision Overlay System uses a beam-splitting prism, high intensity LEDs for shadow-free lighting and a new high definition 1080p camera for easy alignment.

• Quad-Field Imaging for Large/Fine Pitch BGA's: Allows up to four corners of a large component (and its lands) to be viewed under high magnification, providing perfect alignment of outsized BGAs or fine-pitch QFPs.

• Integrated Board Support Wand: Prevents warping or sagging during reflow, is extremely adjustable to clear parts on the bottom of PCB and is easily removed when not in use.

• Power Distribution Graph: Provides a graphical analysis of the top heater output within each zone, helping the developer make necessary adjustments to either the bottom heater utilization, or ramp rate, to maximize thermal performance.

• Sensor Offset: Allows the developer to easily match the pyrometer temperature reading to the actual solder temperature.

-

Manuals

-

Additional Videos